Vertical Packing Machine For Grain/Powder/Sauce

Introduction

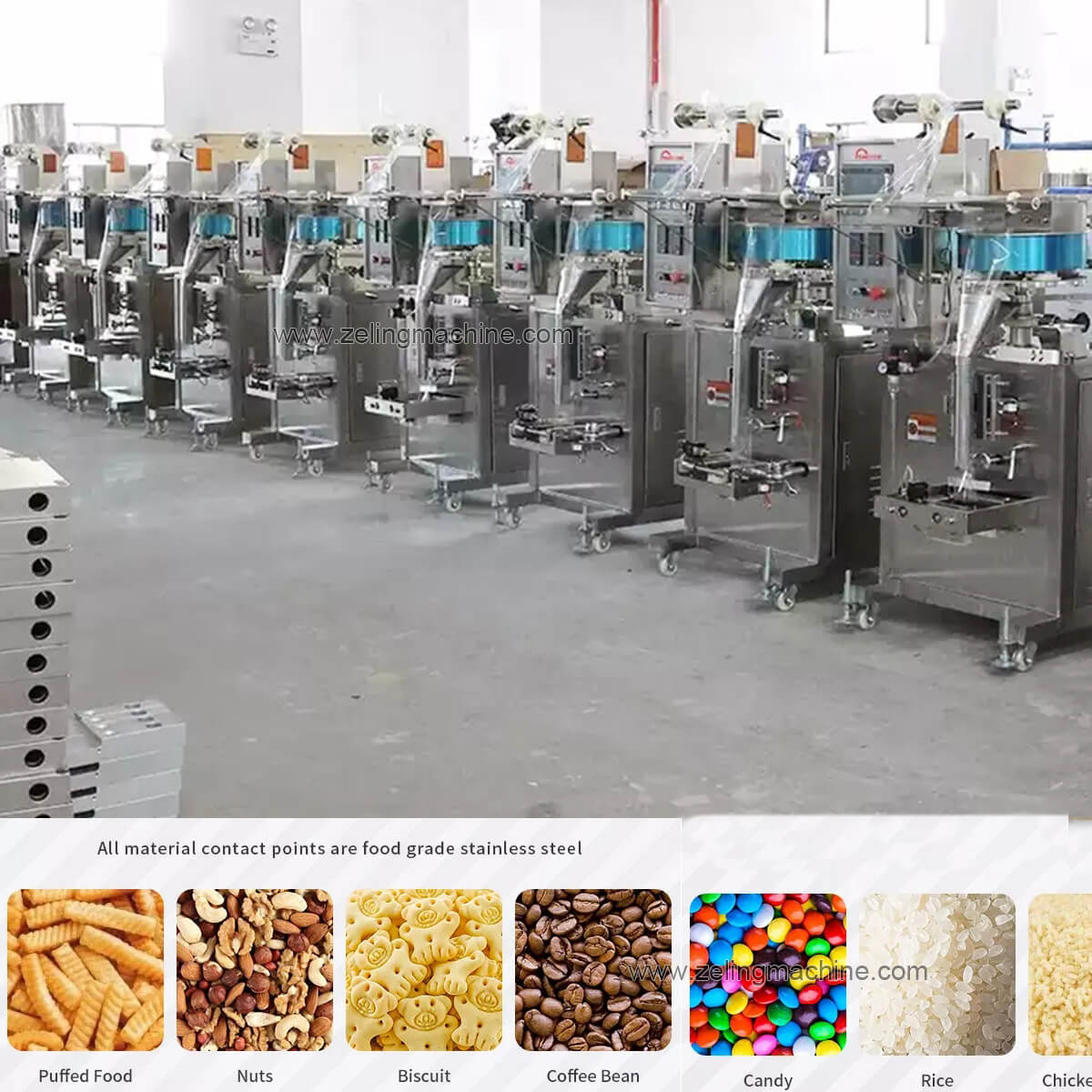

This Machine designed for the automatic package of granule. Such as free flowing grains, pulses, seeds, sugarsalt, coffee beans, maize, nuts, candies, dried fruits, snacks, pet food and many more.

According to customer needs, it can be customized to meet the needs of a variety of bag packaging. Such as back seal bags, 3/4 side seal bags, round corner bags, straight cut bags, special cut bags, etc

| Model | Product | Size(mm) | Weight | Measurement | Hopper | Film width | Bag width | Bag length | Measurement range | Speed | Max film roll |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ZL-160A | Gains | 1100*755 *1730 | 286kg | Volumetric cup | 40L | Max. 320mm | Max. 150mm | 30-200mm | 20-250ml | 10-70 bag/m | 300mm |

| ZL-160F | Powder | 1100*755 *1730 | 286kg | Auger feeding | 16L | Max. 320mm | Max. 150mm | 30-200mm | 1-5ml/ 5-15ml/ 15-50ml/ 50-150ml/ 100-500ml | 10-70 bag/m | 300mm |

| ZL-160Y | Sauce | 1100**755 *1730 | 286kg | Pneumatic pump | 30L | Max. 320mm | Max. 150mm | 30-200mm | 20-100ml/ 100-300ml/ 300-500ml | 10-70 bag/m | 300mm |

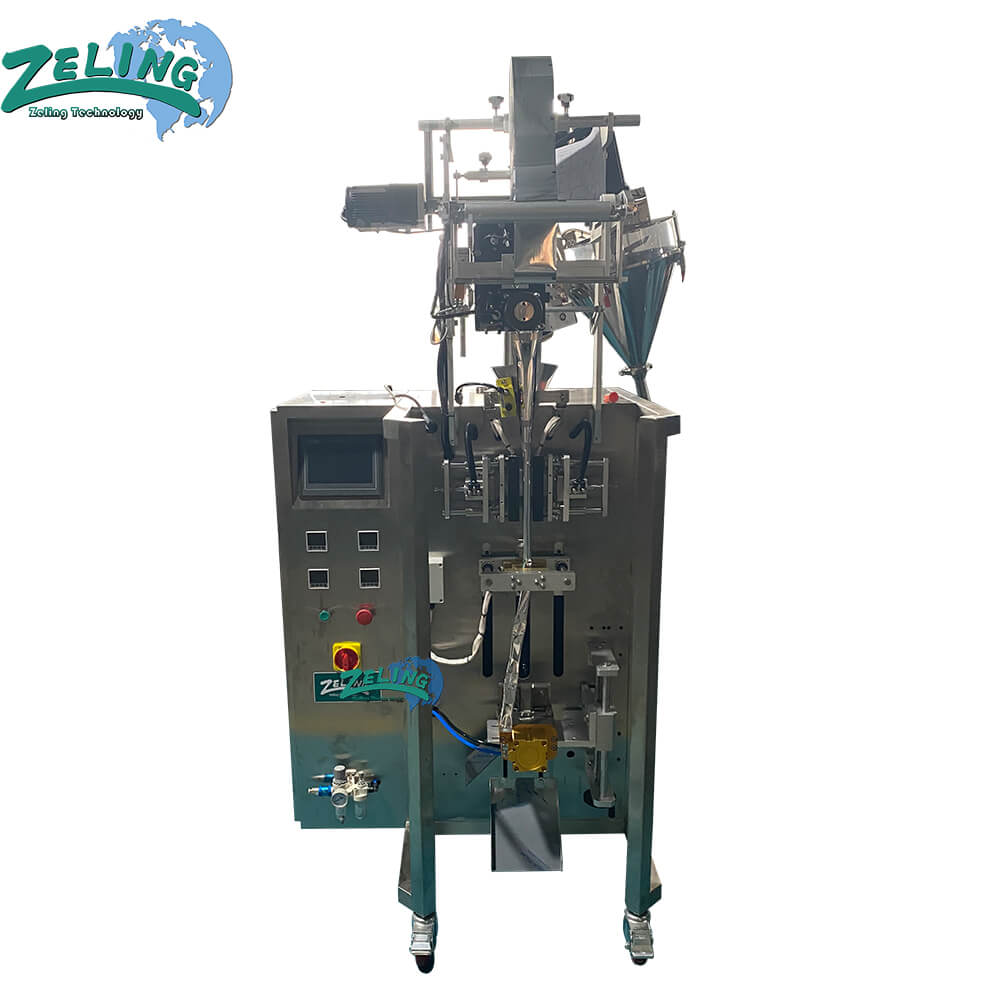

Feature (ZL-160A, grains):

- The overall structure of the machine is compact, sturdy, well-designed, and simple;

- Adopting a photoelectric eye control system and a stepper motor for film pulling, reliable, stable performance, and low noise;

- Adopting variable frequency speed regulation, the operation is more stable, the noise is lower, and the failure rate is low;

- Fully automated from measuring, filling and bag making, date printing to product output, all completed in one go;

- Borrowing the principle of spring pressure knife, pneumatic cutting, and five connected packaging are more precise.

Application:

Suitable for packaging granular solid materials such as puffed foods, peanuts, melon seeds, rice, seeds, monosodium glutamate, beans, popcorn, cookies, etc.

Feature (ZL-160F, powder):

- Screw metering, weight adjustment without tools, stable performance, and simple operation;

- CPU microcontroller control, stepper motor film pulling, screen adjustment parameters, simple and convenient operation;

- Complete the entire process of filling, bag making, date printing, and gas filling (exhaust) in one go;

- Strong expansion function, configurable with packaging and inflation devices to meet the needs of different products;

Application: Suitable for powder packaging of flour, milk powder, soy flour, etc., suitable for product packaging up to 300ml.

Feature (ZL-160A, sauce):

- Pneumatic pump metering, stable performance, simple operation;

- CPU microcontroller control, stepper motor film pulling, screen adjustment parameters, simple and convenient operation;

- Complete the entire process of filling, bag making, date printing, and gas filling (exhaust) in one go;

- Strong expansion function, configurable with packaging and inflation devices to meet the needs of different products;

Application: Suitable for packaging liquid fluids such as tomato sauce, chili sauce, soy sauce, etc.